Just a couple months back we saw German machined aluminum experts Actofive add a 1/2-price, extra-strong Signature X crankset, and now they’re back with an even lower cost crankset upgrade for riders with Pinion gearbox bikes. Last week, we took a quick peek into Actofive’s Dresden workshop to see how the Signature X Pinion Gearbox cranks went from prototype to batch production…

Update: An important note here and an explanation on our changing of the name we use to refer to these cranks. This is an independant project of Actofive and is NOT a collaborative project with Pinion. Read on for more detail.

Actofive Signature X Gearbox CNC-machined crankset

The reason why Actofive created a Signature X Gearbox upgrade option for Pinion gearbox riders essentially boiled down to… why not!

More and more performance mountain bikers are moving to Pinion gearboxes for their added durability, protection from the elements, and unique weight balance at the center of the bike. But there aren’t really many opportunities for customization. And we all know that the kind of people who buy a very niche Pinion gearbox mountain bike, are probably also the type who want their bike to be dripping with custom bits.

Pinion’s stock forged 6061 alloy cranks are pretty boring. And their black anodized CNC 7075 upgrade cranks are that much cooler looking.

And Simon Metzner of Actofive knew he could simply adapt his recent Signature X cranks for something with more shiny bling. Of course, they are also built tough, are lighter than either Pinion option, and can be had in a few pretty colors, too.

Update: Clarification on crankset development

Metzner has informed us of a bit of clarification to make sure their independent role in developing these gearbox-ready cranks is clear. “This is an in-house development by ACTOFIVE/Metzner Engineering. The cranks are not tested and approved by Pinion. The end user therefore has no claim against Pinion when using this cranks. The Pinion guarantee does not apply. ACTOFIVE/Metzner Engineering also accepts no guarantee or warranty claims for Pinion gearboxes. ACTOFIVE/Metzner Engineering only provides a guarantee for the cranks themselves.“

That all sounds reasonable, as they have not intention of representing some relationship with the Pinion company. Only that Actofive appreciates the mechanics and craftsmanship of the MTB-ready gearbox, and wanted to adapt their proven CNC cranks to give Pinion users the option for a potential upgrade and some customization.

Tech details

Actofive CNC-machines the new Signature X Gearbox crankset from 7075-T6 aluminum. And tests them to ASTM F2043-13 / EN 17406 CAT 4 standards – for gravel, XC, trail, and enduro use.

Like the standard Signature X (which shares the exact same profiling), the new Pinion crankarms feature a one-piece design with a machined out backside. That means low weight but high strength and impact resistance. Plus, there are optional crank boots if you want to keep rock strike scratches at bay.

Actofive says the new crankset weigh 420g (left & right arms, including clamping screws). That’s a 55g savings over the stock forged Pinion crankset. Or even 20g lighter than the upgraded Pinion CNC crankset.

The Signature X Gearbox crankarms each use a single M6 titanium clamping bolt instead of two M5 steel bolts on the Pinion arms. Metzner says it provides a cleaner look (almost invisible when the cranks are horizontal) and solid spline clamping. Q-factor is 174mm with Pinion P-line gearboxes or just 166mm with C-line models.

Actofive will also offer compatibility with Pinion’s Smart.Shift electronic shifting system, and combined ON.E Motor.Gearbox.Unit e-drive system for the future.

Actofive Signature X Gearbox cranks – Prototyping, pricing, options & availability

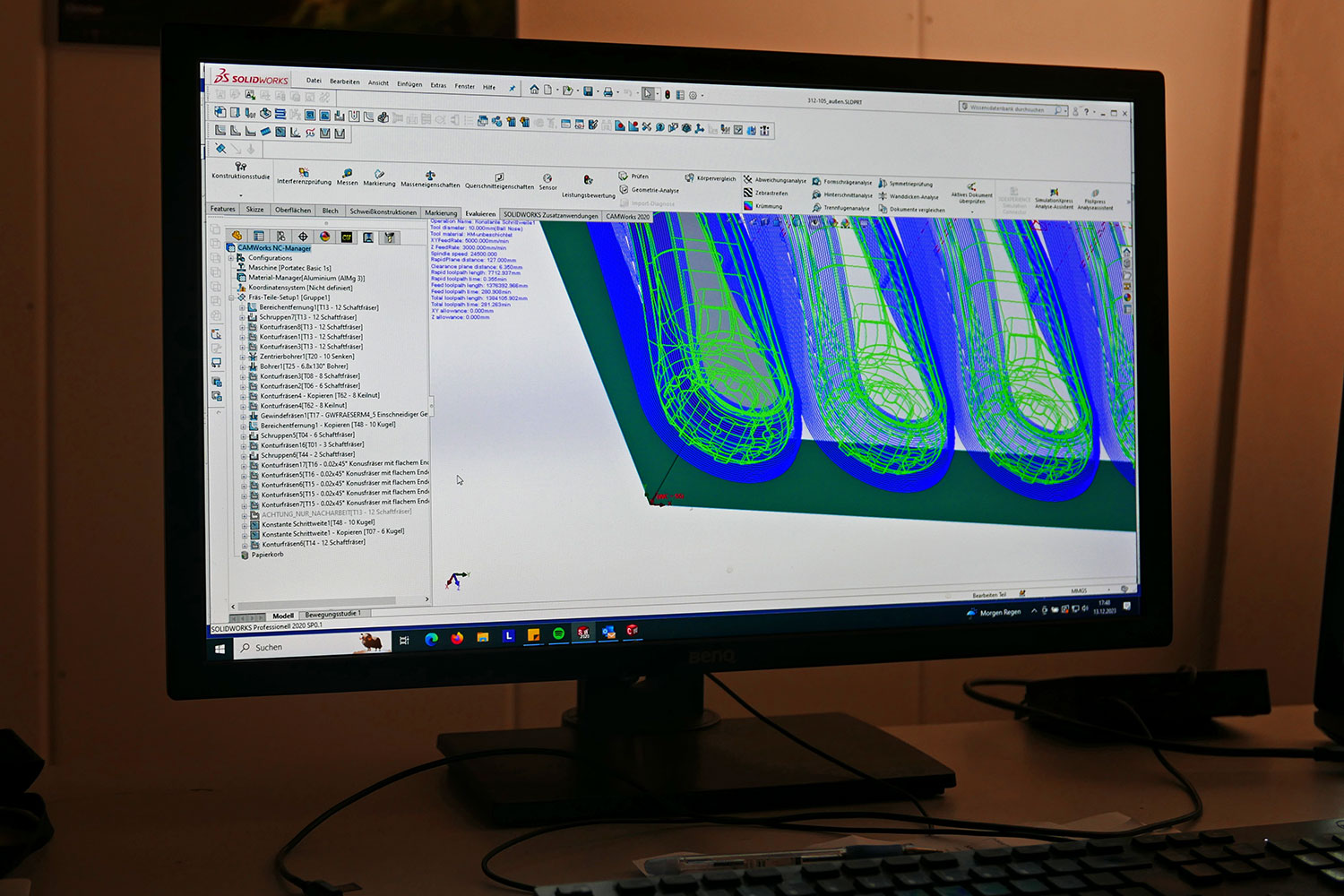

Interestingly, when we popped out heads into Actofive’s workshop, we got to see the transition from prototype development to production manufacturing. What’s especially unique about Actofive is that they manufacture everything in-house out of 7075 aluminum on one smart CNC mill and a lot of creative tooling. Everything is machined from one side out of alloy blanks. Then it gets machined on the second side with custom fixtures that hold the parts in place.

To refine the design and machining process, Simon uses leftover material from mountain bike frame production to work on prototypes. Reuse, before that excess material would be otherwise sent for recycling. At various steps, he go 2 or 3 crank arms out of one off-cut from an MTB front triangle scrap.

Then, we saw him make the switch to production, machining 30 cranksets, tightly nested from one 1m x 1m block of aluminum.

(We’ll dive a bit deeper into Actofive manufacturing in the near future.)

The new Signature X Gearbox cranks have just started their first machining production step now and are open for pre-orders. Initially , Actofive plans to just produce the Signature X Gearbox cranks in 170mm length. But if there is real buyer demand, he could engineer solutions for other lengths, as well.

The Pinion-specific upgrade crankset sells for 369€. Then, pick from 4 standard anodized finishes: silver, black, blue, or grey, plus the extra shiny & deeper raw option. Actofive opens pre-order now for the limited run of Signature X Gearbox cranksets. And then the first finished batch of cranks ships in March 2024.