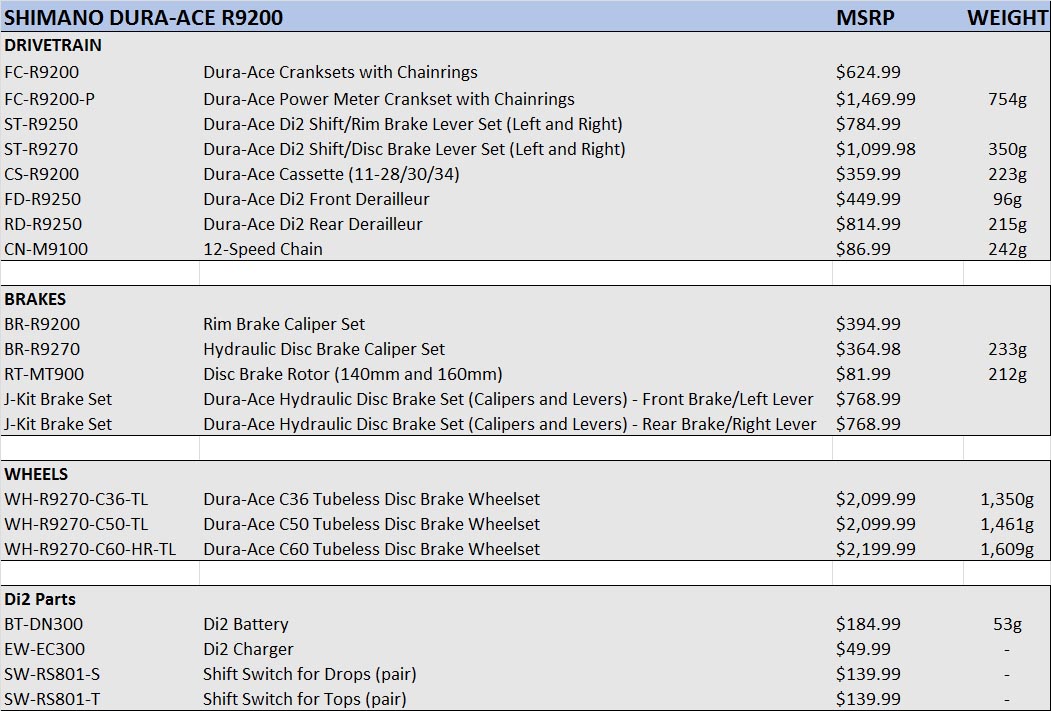

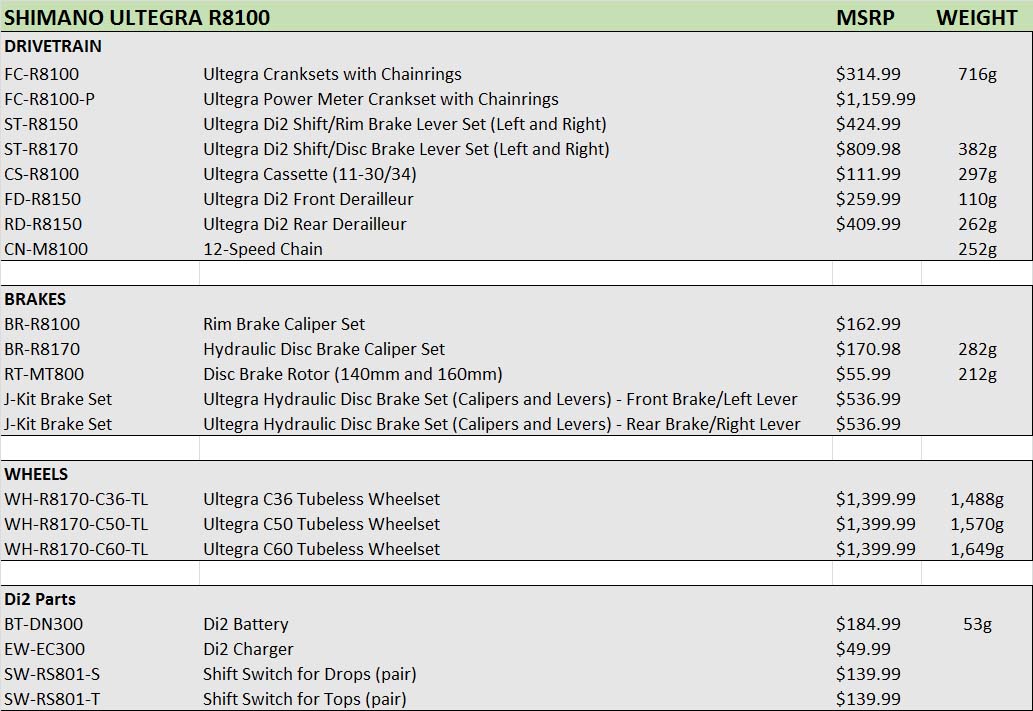

For the first time in history, Shimano is launching their newest Dura-Ace group and the new Ultegra at the same time. That’s right, the new Shimano Dura-Ace R9200 and Ultegra R8100 12-speed groups are here, and they’re wireless, offer the fastest shifting ever, wider range gearing, massively improved braking, and a completely revised charging system. Not only are the two groups launching at the same time, but Ultegra offers nearly the same experience as Dura-Ace, just with a bit more weight (and lower pricing).

Here’s the complete technical overview on what’s new for Shimano 12-speed road groups, followed by complete stories for each group’s initial review, plus a full story on the all new wheels and freehub bodies. Just know this: Yes, there’s still a rim brake set of shifters available, but these two groups are now electronic only… no more mechanical Dura-Ace or Ultegra groups!

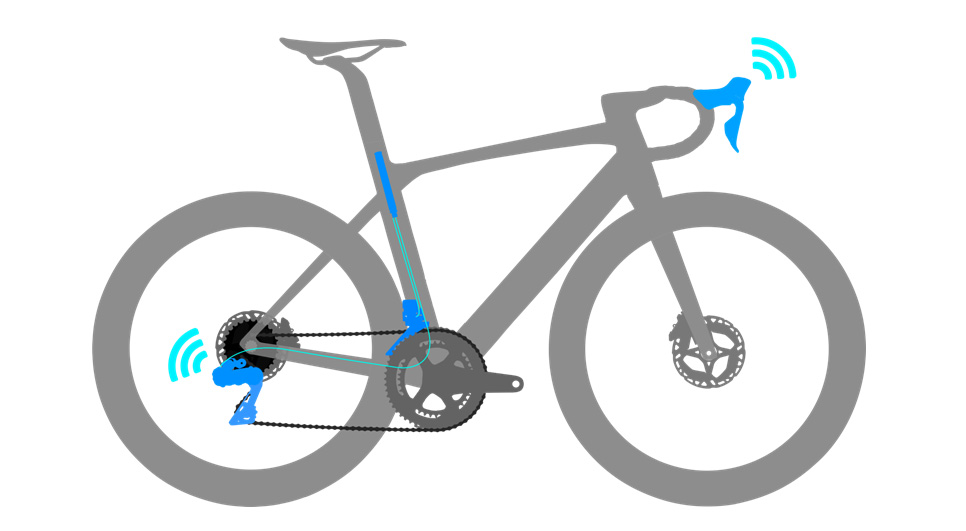

Shimano’s Wired Wireless Di2 System

The new Shimano Dura-Ace and Ultegra groups are wireless…sort of. They have a wireless cockpit, but rely on a battery in the seat tube to power the front and rear derailleurs. Meaning, each shifter lever is completely independent, using coin cell batteries to power their transmitters. Only the brake hose (or cable…keep reading) tethers it to the rest of the bike.

There are a couple reasons Shimano stuck with a wired power source for the derailleurs. But mainly, it’s all about speed and reliability. As Shimano’s Hiroshi Matsumoto put it over a video call, “wireless can not make a rider faster.” Shimano put a huge emphasis on shifting speed with the new groups, and considering that their 9100 group already claims to have the fastest shifting in the industry, making it even faster was no small task. Keeping the battery in the seat post makes the rear derailleur lighter, which supposedly allows it to move faster through the gears. Shimano also points out that the most complicated cable routing is usually at the stem/steerer tube/head tube junction. Since it’s fairly easy to route the wires from the seat post to the front derailleur and rear derailleur (and the new wire requires even smaller passage ways), the choice for a single, larger capacity battery makes even more sense.

But it also opens up possibilities for the future, particularly e-bike integration where the parts could be powered by the e-bike battery rather than the seat post battery.

Another reason is it simplifies charging, since you only have one port. And, thankfully, that charging port moves to the rear derailleur, so there’s no more need for a junction box anywhere else on the bike! That’s because the rear derailleur now functions as the battery charging port, the D-Fly wireless adapter, and the Junction-A, with all of that built into the 215g rear derailleur. Technically there is another charging port if you are running the integrated power meter. Thankfully, it uses the same charging cable as the rear derailleur though. Granted, you will have to have your bike close enough to an outlet to charge the battery with the included 1.5m USB charging cable (or use an extension cord), but there’s also no chance of leaving your battery behind on the charger as you grab your bike and head out for a ride (or losing it mid-ride).

The battery now has three ports, one for each derailleur, and one to run to the shifters if so desired (required on tri/TT bike set ups). That said, we could see them using that third port to power something else in the future.

Expect to get about 1,000 km per charge for derailleurs, and the CR1632 coin cell battery in each shifter should last 1.5-2 years, but… the shifters can also be wired, which is great for e-bikes that already have wiring going to the cockpit. A wired system is said to add about 50% longer battery life as well. Speaking of the shifters…

All New Wireless Shifters

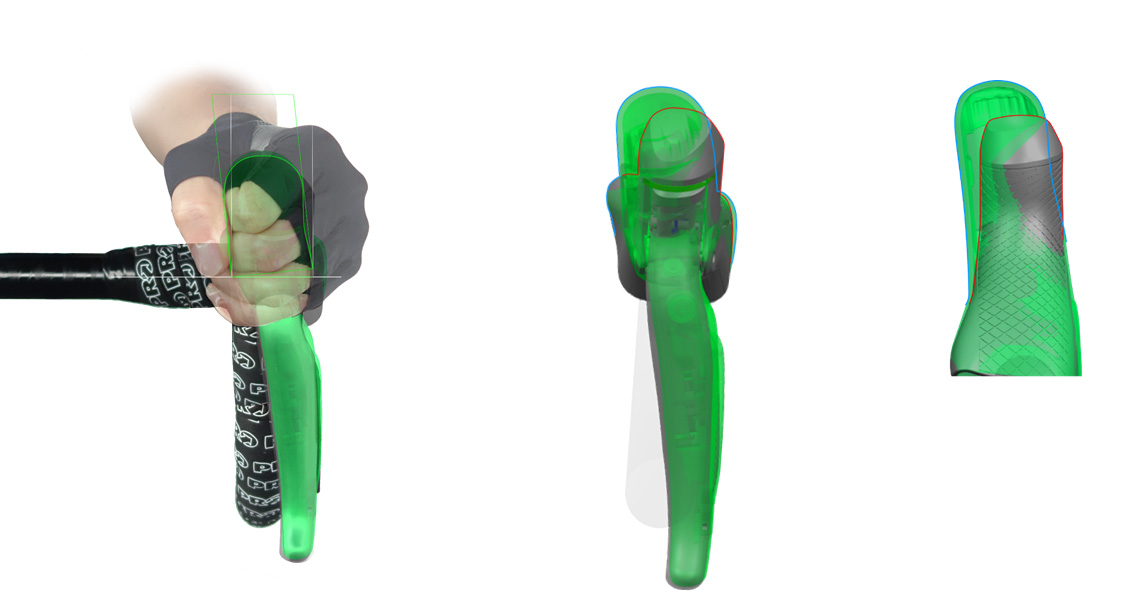

You’ll find an all new interface at the shifters with improved ergonomics, buttons that are easier to operate, and the ability to customize your setup.

Shimano has increased the offset between shift paddles (aka buttons) behind the brake lever while adding additional length to the bottom of the buttons. The offset creates a more distinct tactile ridge between the up- and down-shift buttons, making it easier to know that you’re pushing the correct one…especially helpful if you’re wearing full finger or winter gloves. The increased button length makes it easier to reach them from the drops, and you’ll also find more finger space under the hood for a more comfortable grip.

The hood shape itself is also drastically different as well. Now, the hoods angle in towards the center of the bike which supposedly puts the hands in a more ergonomic position when on top of the hoods.

Each shifter has two wire ports built into it – one for remote shifter buttons (like their Climber’s buttons), and one for wiring them into the main Di2 battery (or an e-bike battery once those systems become available) if you wanted a fully wired system.

There are now three options for remote shift buttons, too, and they’re all much simpler than before. The prior Climber’s shift buttons actually had circuitry in them, meaning you couldn’t really hack the system to use different buttons. Not that we would, but it’s nice to know that the new ones are, quite simply, just a switch that closes a circuit to trigger a shift. You’ll have the option of the SW-RS901-S which takes the place of the Sprinter Switch on the drops and has a longer 260mm wire, the SW-RS801-T which is the new Climber switch meant for the tops of 31.8mm bars with a shorter 100mm wire, and a new OEM-only mini-button that can be integrated directly into a handlebar port, leaving the wiring inside the bar.

E-Tube Customization

Using the newest version of the E-Tube smartphone app, you’ll also be able to customize your shifting set up. That includes toggling between synchronized (front derailleur shifts automatically to keep in the ideal gear range) or semi-synchro shifting modes, adjusting multi-shift settings, setting shifting speed, connecting with third party cycling computers, and customizing what each shifter button does—including the third button which is on top of the hood, operated by your thumb.

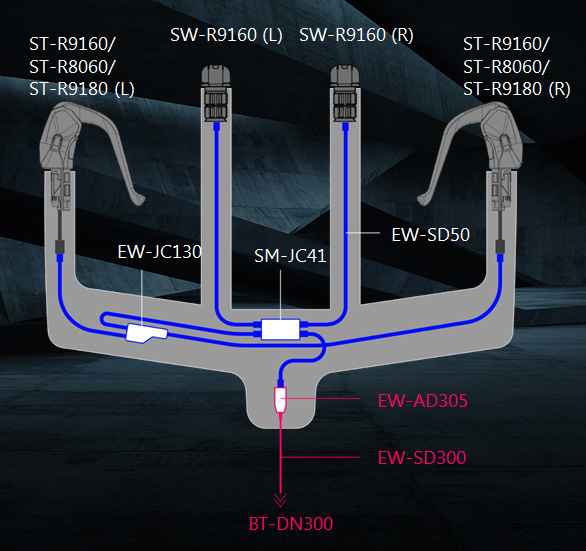

What about Tri/TT bikes?

Unfortunately, there won’t be any new wireless shifters for Tri/TT bikes for now. However, Shimano’s existing Tri/TT cockpit is the only carryover from 11 speed that is compatible with the new 12 speed parts—with an adapter of course. You’ll need to use the EW-AD305 wire adapter which will allow you to plug in an existing Tri/TT cockpit wire set up into the new EW-SD300 wire and connect it to the new drivetrains. The nice thing is that this means if you already have your aerobar set up dialed, you can upgrade to the new groups by just plugging it in.

Even the Wires are New (kind of)

When it comes to Shimano’s Di2 drivetrains, the smaller EW-SD300 wire is new. However, it’s been used on the e-bike side of things for awhile now, so it’s technically not new to Shimano. But the wire is notable due to its smaller size and its ability to carry more information. So while the new Shimano drivetrains are compatible with all existing frames, it’s possible manufacturers could make frames with even smaller wire ports in the future. Note that the new wires do require a new tool (TL-EW300) for installing and removing the connectors to prevent any damage to the system.

A Lot Faster Shifting

Out of the box, the shift paddles will work the same as before, albeit with faster shifts. The rear derailleurs shift 58% faster than before, and the front derailleurs are 45% faster.

Some of that speed comes from a new, faster processor, and a wireless protocol that uses smaller data packets. Shimano already had the fastest electronic shifting, so these new numbers are almost mind blowing, but let’s put it into context.

Shimano says the new Di2 has 4x faster processing speed compared to Zigbee, which, in Shimano’s words, is “the other wireless protocol that’s common out there”. They also say it has 75% less power consumption, but more importantly, a much smaller (90% smaller) “packet size” of data, which lowers the probability of interference.

According to the information provided, that means that shifts are faster for the rear derailleur both in terms of communication time between the shifter and derailleur, and the moving time of the derailleur itself. Interestingly, the front derailleur actually has a longer communication time between the shifter and the derailleur, but a much faster moving time of the derailleur itself which still nets a 45% faster shift up front. That’s because the signal now must travel from the front shifter to the rear derailleur, along the wire to the battery, then to the front derailleur—but the increase in derailleur speed more than makes up for this delay.

And it’s not just shifting up the cassette either. Thanks to Hyperglide+ moving over from the MTB side, shifting is faster down the cassette now, too. Hyperglide+ was introduced on Shimano’s latest 12-speed mountain bike groups, starting with XTR, then XT and SLX. It adds additional shaping to the cogs along with a specific chain to speed up the shifts down the cassette to harder gears by 66%, even under power, which was the upgrade from standard Hyperglide.

Backwards Compatible Cassettes!!!

More gears probably means a new freehub standard, right? Well, there is a new freehub for Shimano’s own Dura-Ace wheels that is 12 speed specific—BUT, every 12 speed Shimano road cassette will fit existing HG spine freehub bodies. That’s right, you can run the new Dura-Ace and Ultegra cassettes on all of your existing wheels!

How’d they do it, and why? Shimano wanted to build a lighter hub for their wheels, but the existing HG spline design was the road block. If they made the HG spline freehub body any lighter, it wouldn’t pass their own (very strict) quality standards in terms of the cassette cogs digging into the soft alloy. So they created the new 12s freehub body with more splines to shoulder the load to address this issue. Note that it’s not MicroSpline, but something completely different.

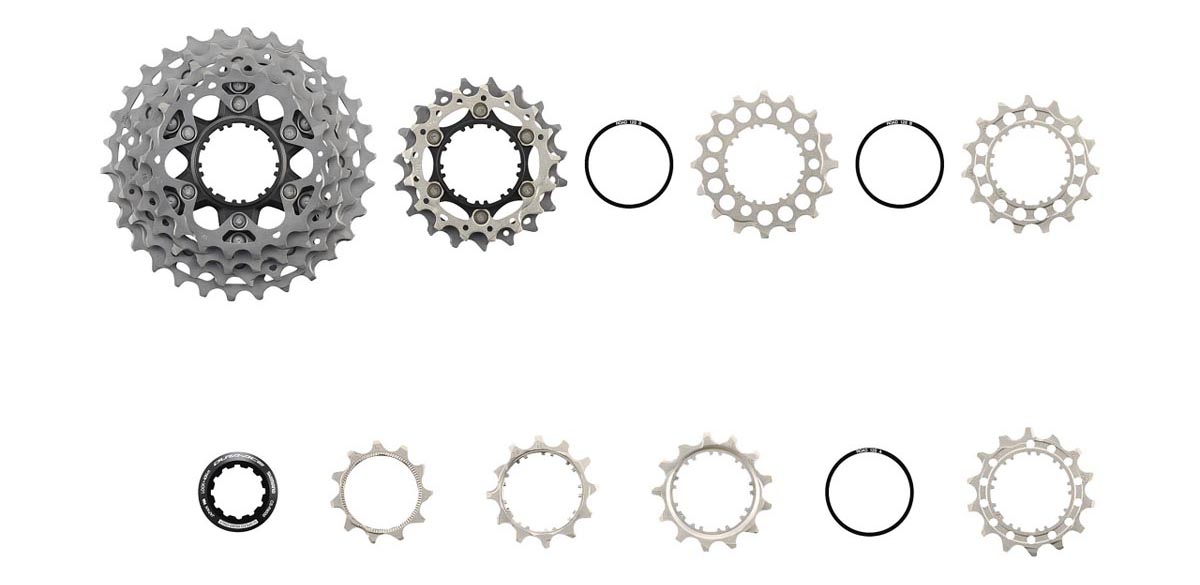

The new cassettes mount onto either design and use an arrow to indicate the key spline which is the same on both freehub bodies. To make the wider cassettes work on a narrower freehub, the last cog doesn’t actually interlock with the freehub body, instead it’s keyed into the cog below it to keep it from turning. Then an extra long cassette lock ring keeps everything tight.

One thing to note with the cassette design—there are now two different spacer thicknesses with one ‘A’ and two ‘B’ spacers. The order is as shown above, with the ‘A’ spacer closest to the lockring, followed by the two ‘B’ spacers as you move towards the hub.

Initially, two cassette options will be offered with wider 11-30 and 11-34t gearing in both Dura-Ace and Ultegra. We know that Shimano is all about the optimal ‘gear steps’, and these new cassettes are no different. The 11-30t is said to provide the “sweet spot” for shifting with a 15, 16, 17t progression in the middle of the cassette. The 11-34t instead goes 15, 17, 19 in order to jump up to the 34t for ultra low 1:1 gearing. Gearing steps are the same for Ultegra and Dura-Ace Cassettes.

12 speed Cassette Gear Steps

- 11-30t: 11, 12, 13, 14, 15, 16, 17, 19, 21, 24, 27, 30

- 11-34t: 11, 12, 13, 14, 15, 17, 19, 21, 24, 27, 30, 34

All New Cranksets

Not surprisingly, Shimano is continuing with their Hollowtech II crankset design with a 24mm spindle only. The cranksets also refrain from moving to carbon fiber with a Hollowglide structure which is said to cut weight while maintaining the strength and stiffness needed for precise shifting. Sticking with their ‘bigger is better’ for drivetrain efficiency, Shimano is still focused on providing the “most efficient drivetrain on the market” partially through the gearing options provided. That includes a massive new 54-40T option for Dura-Ace which probably won’t be the choice of average riders, but the racers will dig it.

That’s evident in the 54-40T option only being offered in Dura-Ace, though since the Ultegra cranks use the same BCD, you’ll be able to get 54-40t chainrings for your Ultegra crank if wanted. Otherwise, both the Dura-Ace and Ultegra cranks will be offered in 50-34T and 52-36t options allowing for a 1:1 low gear if run with the 11-34t cassette.

Now with the addition of a 160mm crank arm length, Dura-Ace cranks will be available in seven sizes including 165, 167.5, 170, 172.5, 175, and 177.5mm lengths. Ultegra has a few less, coming in 160, 165, 170, 172.5, and 175mm lengths. Both cranksets have a q-factor of 148mm.

Dual Sided Power Meter Option

For those who want to measure their power output, both Dura-Ace and Ultegra have a crankset option with an integrated Dual Sided power meter. While the tech is similar to what Shimano has offered before, the power meter has a repositioned transmitter and charging port (same port and cable as the rear derailleur) to make it easier to use.

The rechargeable lithium ion battery provides up to 300 hours of ride time, and the Bluetooth LE/ANT+ power meter is now accurate to +/- 1.5% utilizing a proprietary strain gauge. Zero offset calibration can be done quickly with a switch on the transmitter, and the software automatically compensates for temperature changes.

Power meter cranksets will be offered in the same specs as their non-power meter cranks, meaning a few more size options for Dura-Ace.

New Rear Derailleurs

Besides the speedier response and integrated charging port, there are a few more new features in the Dura-Ace and Ultegra 12-speed rear derailleurs. For starters, they have D-Fly wireless transmitters built into them. Using Shimano’s proprietary wireless Integrated Circuit, this is how it receives the shift signals, which carry along the wire to the battery, and then to the front derailleur as needed. They can also use Bluetooth LE or ANT+ wireless protocols to communicate shift and gear data to compatible head units from Garmin, Wahoo, etc.

The rear derailleurs also allows for larger cassettes, from 11-28 all the way up to an 11-34. That means a single rear derailleur for any gear combination for Dura-Ace and Ultegra.

While the rear derailleur is a Shadow design, it does not have a clutch. Shimano is clear – these groups are for road. If you are riding gravel, you should be looking at the GRX lineup, not Dura-Ace or Ultegra. According to Shimano, adding a clutch would slow down the shifting, and is not necessary for road riding. Note that out of the box, the derailleur cages have a slight twist to them – this is normal, and not an indication of a defective derailleur.

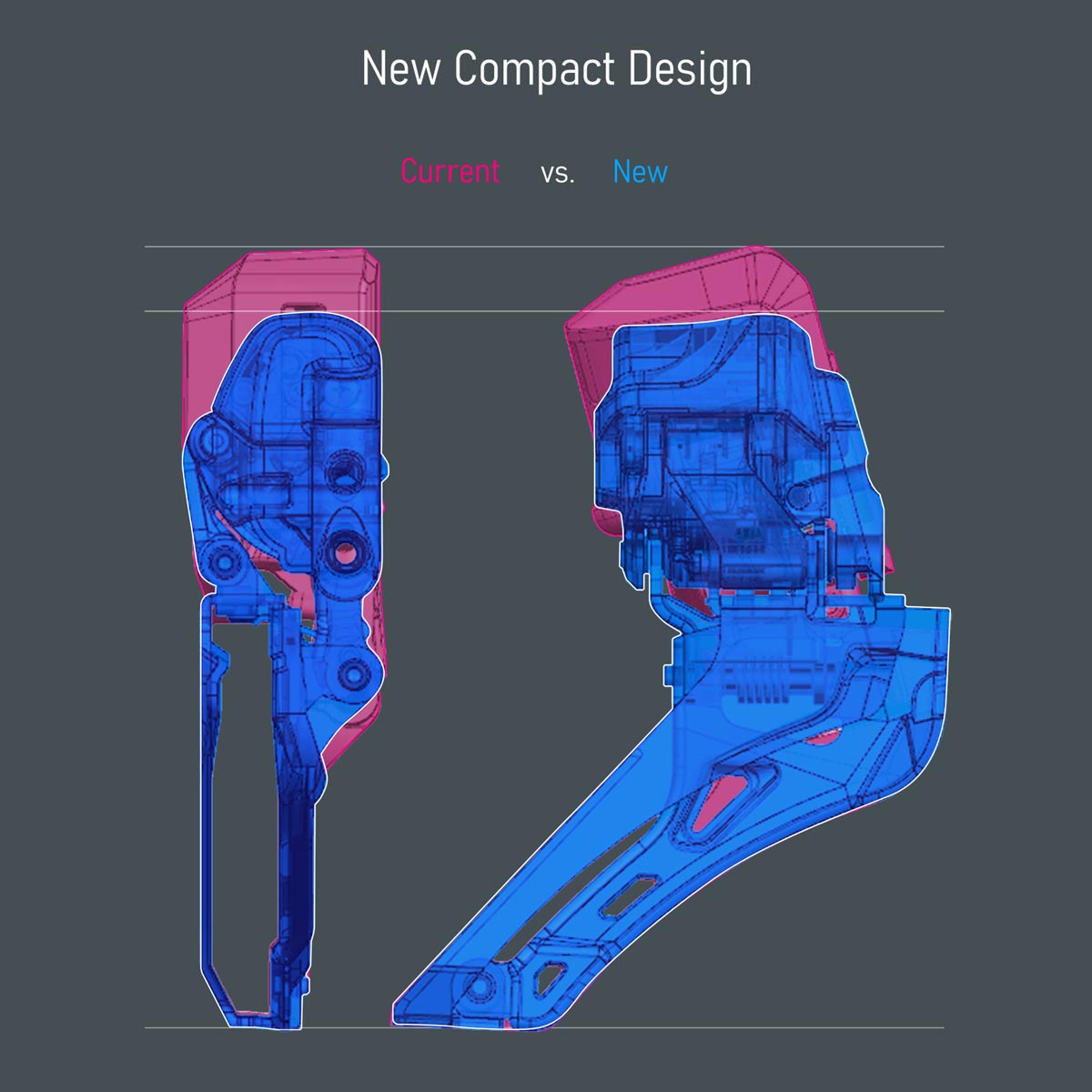

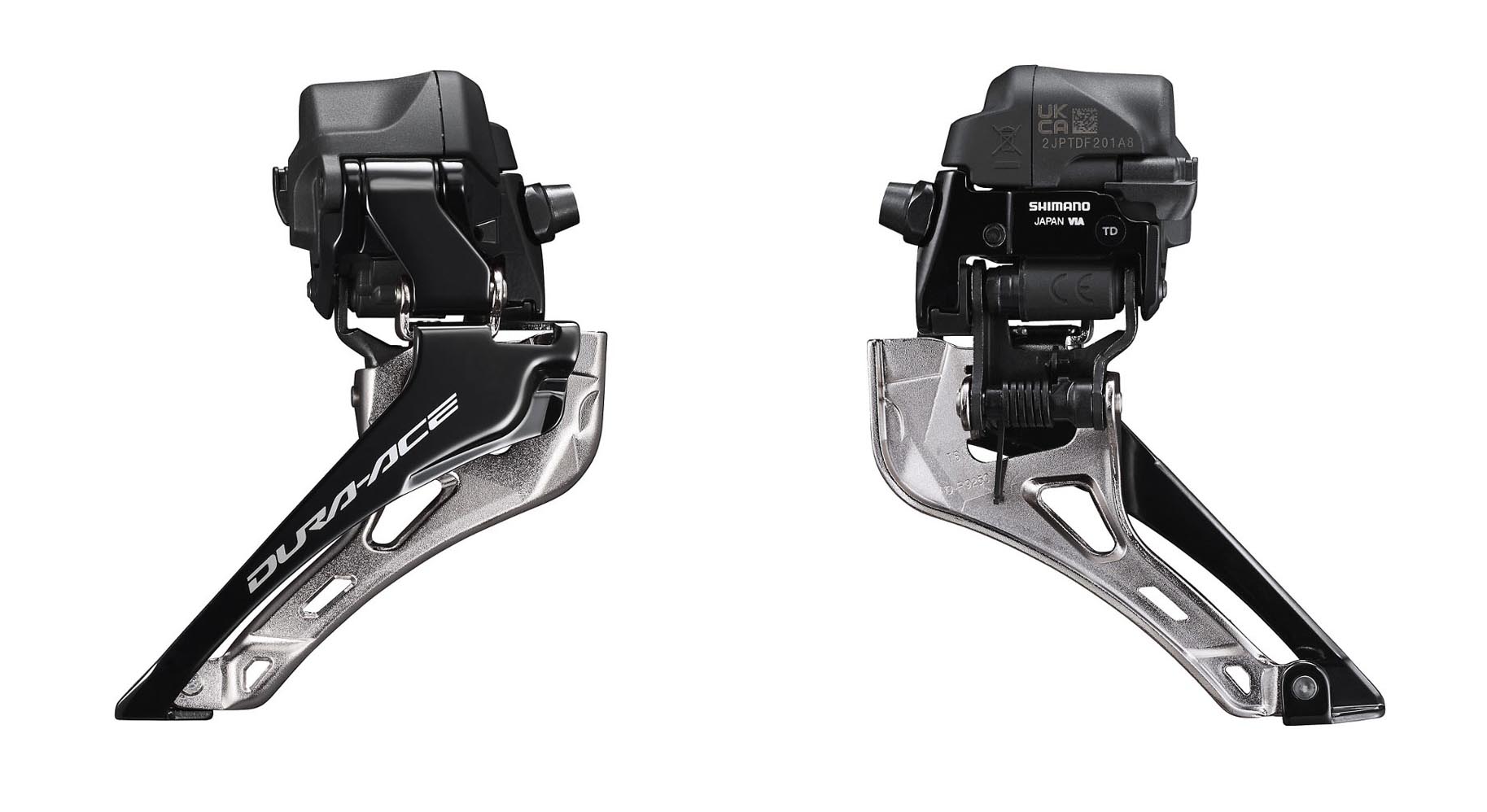

New, Smaller Front Derailleurs

Thanks to a new link structure, we not only get smaller front derailleurs but lighter as well. Continuing their dominance in the world of front derailleurs, the new FD-R9250 is just 96g and has a 33% smaller frontal projected area. As mentioned, it’s their fastest front shifting ever by 45%, and the derailleur has a top gear tooth capacity of 50-55t.

Best Disc Brakes yet

It would be easy to overlook the brakes in the midst of all the drivetrain changes, but both the Dura-Ace and Ultegra drivetrain get big upgrades from relatively small enhancements. Everyone hates brake noise, especially on the road. To keep things quiet, the brake calipers now offer 10% wider pad clearance which means the pads pull back farther from the rotor to prevent any rubbing.

Yet, even with more space between the pads and the rotors, the new Servo Wave brake levers actually make the pads engage with the rotor sooner, while offering more modulation. So there’s a shorter initial stroke of the lever before you start to feel the pad ‘bite’, and then a 13% longer stroke to offer finer control of the braking power to prevent lockup.

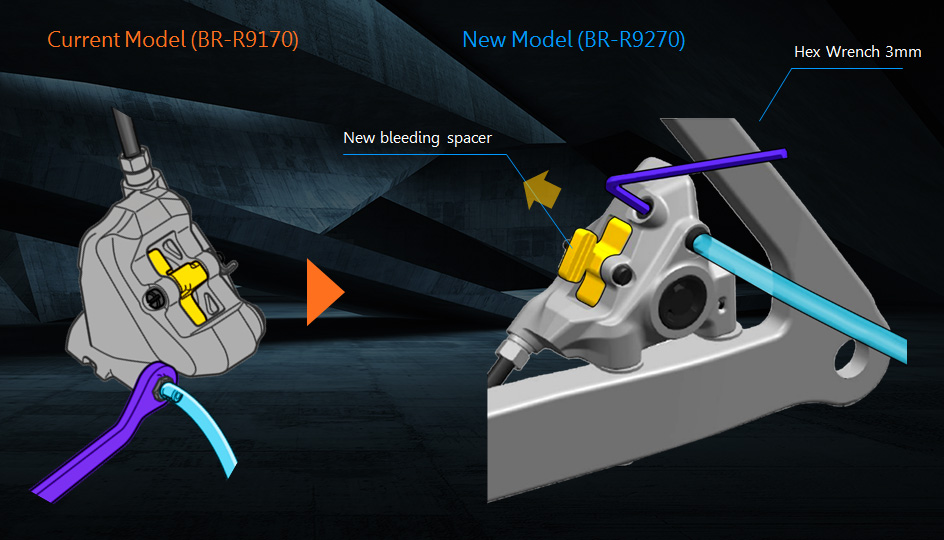

Thanks to a redesigned brake caliper, the bleeding process is also easier with a separate bleed port and valve screw (bye bye hose-popping-off-the-bleed-nipple-as-you-try-to-turn-it). It’s also possible now to bleed the brakes without removing the caliper from the frame. While both groups get the updated design, the Dura-Ace caliper is one piece, while Ultegra is two.

Notice some pro tour riders using Shimano MTB brake rotors instead of the road models? Apparently, that wasn’t an accident. Shimano has found that their RT-MT900 XTR rotor offers a 66% reduction in heat compared to their previous SM-RT900 Dura-Ace rotor, so there isn’t a new ‘Dura-Ace’ brake rotor. Instead, you’ll simply use the existing RT-MT900 XTR rotors, though there will be a different internally splined lockring included for the road with its own part number. With Ultegra more in line with XT, Shimano will pair the RT-MT800 rotor with Ultegra brakes. Additionally, the BH90 brake hoses, brake pads, olives, and barb inserts remain the same.

As mentioned, there will also still be a rim brake spec offered, though in Shimano’s words, it will be “tough to find.” Obviously, the majority of road bikes have moved onto disc brakes, so those have been prioritized (and ordered much more by OEMs). The rim brake option is there for pro teams or the rare instances where a rim brake option is required. Note that while the rim brakes are mechanical, the drivetrain will still be electronic only.

As mentioned, there will also still be a rim brake spec offered, though in Shimano’s words, it will be “tough to find.” Obviously, the majority of road bikes have moved onto disc brakes, so those have been prioritized (and ordered much more by OEMs). The rim brake option is there for pro teams or the rare instances where a rim brake option is required. Note that while the rim brakes are mechanical, the drivetrain will still be electronic only.

No New Chain, or Pedals, or Bottom Brackets Either

It’s a similar story for the chain as well. Thankfully, new 12 speed road groups will use the same 12 speed Hyperglide+ chains already offered for Shimano MTB groups. For now, the Dura-Ace PD-R1900 remains unchanged as well. The same can be said for bottom brackets like the BB-R9100 and SM-BB92.

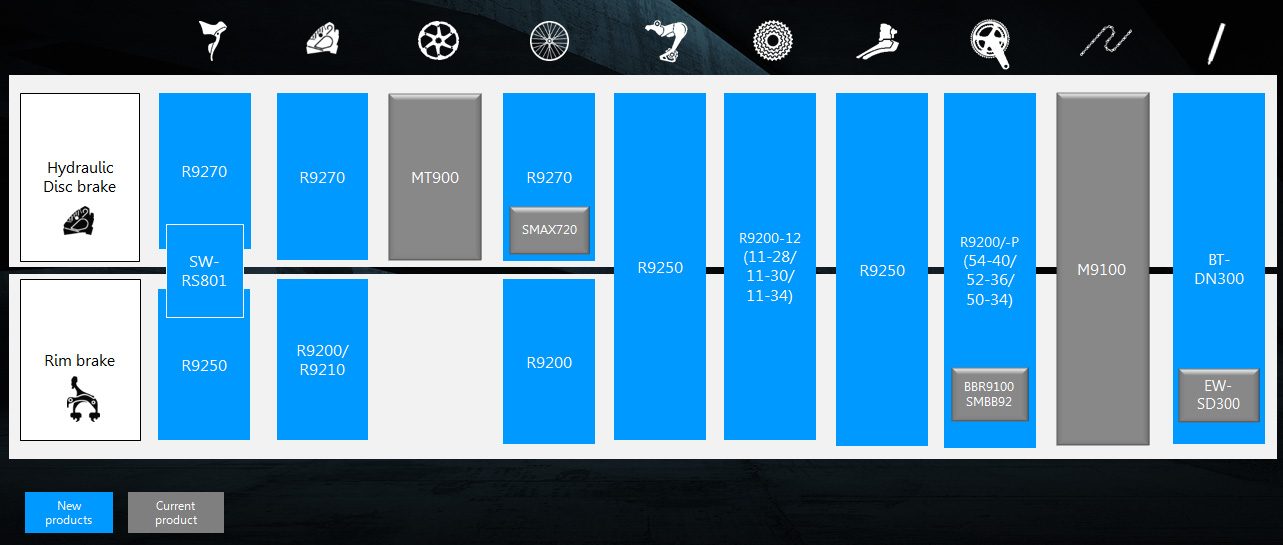

The chart above shows all the new products for Dura-Ace R9200 in blue, and existing products in grey.

What about wheels?

Those are completely new too—but since this post is so long already, we’ve covered those in a separate post here.

What’s the Weight?

While some of the claimed weights are still TBA, Shimano claims that this is the lightest 12 speed electronic drivetrain with hydraulic disc brakes on the market. Compared to the previous R9100 series, R9200 only added about 21 grams for a total system weight of 2,506.5g.

Pricing and availability

All of this new tech is great, but when can you actually get your hands on it? According to Shimano, complete Dura-Ace bikes will be available as early as September, 2021, while aftermarket components will likely be available starting in October, but in limited quantities. Ultegra will follow, likely a month or two behind. We’ll see!